Pyrotek part of largest rolling-stock project in WA history

The challenges

Pyrotek has reached another project milestone supplying the transport industry. Our acoustic and thermal insulation materials specially designed and engineered for rolling stock are part of the METRONET Railcar project in Perth, Western Australia (WA). The project will bring 246 new electric and 6 new diesel railcars over the next 8 years. Perth’s population is expected to grow from 2.02 million in 2017 to 3.5 million by 2050 (Perth and Peel @ 3.5 million) so the METRONET Railcar Program, delivering additional trains to service the expanding public transport network, is crucial to the growth management and meeting the city’s future infrastructure needs. Pyrotek products installed in the trains will help to substantially reduce noise levels, improving the safety and comfort to approximately 1,200 passengers at any given time.

The project is the largest ever railcar contract in the history of Western Australia and has been awarded by the Public Transport Authority of Western Australia (PTA) to global leader in rolling stock manufacture – Alstom. The METRONET Railcar Program required Alstom to provide 50% local content for the manufacturing of the new railcars, aiming to revitalise the train industry in Western Australia. For Pyrotek, a global manufacturer with locations worldwide including Australia, this was an easy procurement factor to work with. With the shells of the trains being built in India, bogies made in WA and AC units in Germany, the new C-Series trains are going to be assembled and equipped with Pyrotek solutions at Bellevue in Western Australia, a purpose-built new facility and one of the most technologically advanced train manufacturing and maintenance sites in Australia.

UNDERSTANDING THE PROJECT

Alstom procurement team approached Pyrotek Australia based on their positive relationship with our facility and team in India - Alstom’s main manufacturing plant location. Technical discussions regarding the acoustic and thermal insulation materials to be engineered and used specifically for this project started in May 2020, the initial request being phenolic-faced plywood flooring with premium acoustic performance. Quickly realizing Pyrotek had a lot more to offer, Alstom brought additional materials into the selection and established Pyrotek a preferred supplier of insulation. The main project objective for Pyrotek was to maximize Western Australia content for the insulation supplied, which was quite difficult keeping in mind that most of the raw materials had to come from overseas. One of the most challenging tasks was to find the right supplier of the plywood panels for the flooring system as very few places around the world supply plywood in sheets large enough for this project. Pyrotek had even gone the extra mile and moved its facility in WA to a much larger one to be able to satisfy the demand, supply the products required on time, and further increase WA content.

The solutions

Pyrotek R&D Centre played a crucial role in the long list of external and internal testing carried out to make sure the flooring panels are suited for purpose. Dynamic loading was one of the most extensive tests carried out with the assistance of the University of Technology in Sydney and required 2 months of continuous testing to complete. Internal testing was carried out on the installation method of insulation in the ceiling cavity as Pyrotek proposed a new, more time-efficient way. This, being a first for Alstom, required the solution to be thoroughly tested. Pyrotek Engineering Centre in Australia contributed immensely as numerous 2D drawings from CAD data had to be prepared, taking up a substantial amount of engineering time.

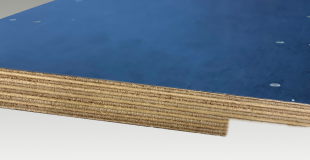

The first supply of the parts to the C-Series trains took place in May 2021. Materials supplied include specially engineered acoustic flooring panels - Subdue® TR, together with additional sound and thermal insulation materials for ceiling and wall cavities. Subdue® TR are multi-layered, internally damped noise barrier floor panels constructed from layers of birch veneers. Combined with a premium acoustic barrier, these create Subdue® TR Plus for an even higher level of noise reduction. Both work by reflecting, absorbing and damping the vibration and transmission of sound through the floors, reducing the noise generated from the train underbody and track noise. Lighter Subdue TR is installed in the middle section of the carriages in order to prevent from adding unnecessary weight to the overall weight of the car. Subdue TR Plus, which also incorporates the acoustic barrier in the floor panel, is installed in sections over the bogies to reduce track noise transmitting into the carriage from the wheels.

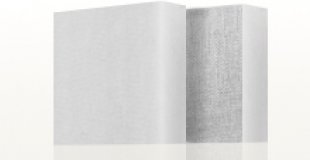

Additional acoustic and thermal insulation materials were part of the complete solution. Sorberwool, lightweight and fire resistant on its own, was used in the flooring cavities and around the door perimeter. Sorberpoly 2D, consisting of 2D non-woven, ultrafine polyester fibres, was installed in the carriage walls and ceilings. Both products are designed to offer excellent acoustic and thermal insulation properties and are faced with a durable, flame retardant glass cloth (GC) or aluminium foil-covered glass cloth (AGC) to provide extra protection to passengers in case of fire.

Pyrotek understand the responsibility that goes hand in hand with a “preferred supplier” label, making sure every delivery arrives on time, with proper packaging and minimal installation requirements. When nearing the supply stage and final delivery, Pyrotek went the extra mile to assure on-time delivery for the METRONET project, arranging a number of raw materials to be airfreighted in order to meet the timelines required for the project. Multiple additional components had to be developed as part of the overall supply package, right down to the delivery method of the flooring panels to enable easy handling and installation in the carriages. This was further enhanced by providing all materials precut and in kit form.

The results

Materials specified for installation in rail carriages must comply to strict fire standards. The prerequisites in terms of the fire performance for this project were HL2 R1 and R10 according to EN45545-2. Pyrotek have exceeded these requirements with all supplied materials complying to the highest possible fire requirement being HL3 for both R1 and R10 categories. The C-series trains for the METRONET Railcar Program will boast higher levels of acoustic and thermal comfort and improved energy efficiency together with an uncompromised level of safety - all delivered thanks to Pyrotek’s advanced & proven insulation materials, in full compliance with or even exceeding rail and fire standards. The first C-series railcars are expected to go into service in 2022 with passenger comfort and safety never better.