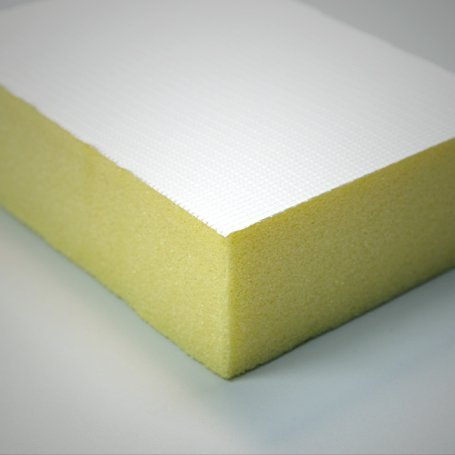

coverings specified to US MIL Spec DOD-I-24688, Amendment 1

CLASSIFICATION

Type I - unfaced (thermal and acoustic absorptive) panel

Type II - faced panel

Class 1 - FG Cloth - Fibrous glass cloth faced (thermal) Class 2 - slotted base board faced with perforated fibrous glass cloth (acoustical)

Class 3 - Faced with primer coated aluminized polyester/aluminium foil reinforced with a fibrous glass scrim

Class 4 - faced with primer coated aluminized polyester/aluminium foil reinforced with a fibrous glass scrim laminated to a lightweight fibrous glass cloth

Class 5 - faced with primer coated white polyester film reinforced with a fibrous glass scrim