high performance barrier-absorber composite

Sorberbarrier is a unique composite noise control product that offers excellent noise transmission loss and high noise absorption. It was developed to reduce noise in industrial and domestic enclosures, OEMs, and marine markets.

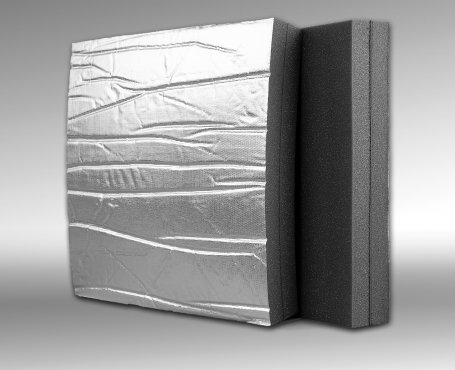

Sorberbarrier combines the superior performance of the flexible mass barrier Wavebar® with the high absorption properties of Sorberfoam™. Wavebar is laminated to the Sorberfoam layer to alter the natural absorption curve, enhancing sound absorption in mid to high-frequency ranges.

Sorberbarrier is available in various surface-facing options to meet specified design requirements. Pyrotek offers aluminium glass cloth (Sorberbarrier AGC), metallised polyester (Sorberbarrier M), polyurethane film (Sorberbarrier PU), and perforated vinyl (Sorberbarrier V).

The innovative construction of the Sorberbarrier places the mass barrier between two layers of absorbing foam, effectively separating the barrier from the structure. This unique design allows it to remain flexible at all times, significantly increasing the noise transmission loss.

Tests have revealed that altering the thickness of foam that separates the noise barrier from the structure improves the product’s performance in some frequencies without an increase in overall weight.

Sorberbarrier is not just a one-size-fits-all solution. It intelligently targets specific frequency ranges, making it the most versatile product for controlling noise in the market place. No matter your industry, Sorberbarrier can adapt to your needs.

For pressure sensitive adhesive (PSA) installation, please refer to installation instructions.