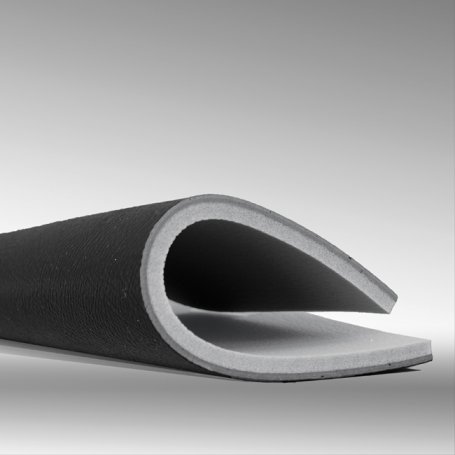

decoupled flexible noise barrier floormat

Soundmat PE is a low profile, high mass noise barrier, bonded to a flexible closed cell foam decoupling layer. The noise barrier is faced with a highly abrasion resistant vinyl wear layer.

Based on Wavebar® technology, this material is an economical, and acoustically effective, material for use as a floormat to reduce sound transmission. It does not require further protective layers. When applied over the floor, or firewall, of vehicles Soundmat provides a significant increase in transmission loss.

Soundmat can also be laminated to walls and partitions to increase transmission loss. Soundmat offers a valuable increase in transmission loss in the critical frequency region for stiff panels and partitions, where coincidence and resonance effects are a concern.

The foam is hydrolysis resistant. It is especially suited for use in wet and humid areas such as in marine or tropical environments and in mobile equipment.

The closed cell nature of the foam eliminates ingress of water, and therefore reduces the potential for corrosion.

Soundmat can be fabricated by sewing or gluing and is available in pre-cut sizes and shapes.