Wavebar SIL

High performance silicone barrier - conforming to MIL-PRF-24699A (SH) Type II for military and navy

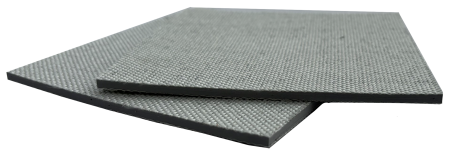

Wavebar® SIL is a high-performance, flexible, mass-loaded silicone noise barrier combined with fibreglass fabric. With fiberglass fabric on both sides of the acoustic barrier, it was double faced for maximum protection and designed for the military and navy industry, conforming to MIL-PRF-24699B(SH) Type II.

Pyrotek developed the high temperature and tear resistant noise barrier with excellent fire resistance and thermal insulation to withstand high temperatures (482F, 250C). Wavebar SIL, designed with the original Wavebar soundproofing properties and added ‘flame shield’, is

designed for military vehicles and navy ships.

Stiff and lightweight panel constructions such as light gauge metals or rigid boards typically have coincidence dip resonance which allows noise to transmit through a construction. The coincidence dip is dependent on the material’s stiffness and thickness and occurs at the point where the sound transmitted through the structure matches the natural frequency of the panel. Wavebar® SIL shifts the coincidence dip to frequencies limiting its impact, thereby maintaining the performance of the product.

The dense mass layer reflects and absorbs the transmission of sound, reducing the critical frequencies generated from mechanical equipment, engine noise and electronic audio technologies.

Applications

- Military vehicles

- Machinery spaces, cavities and enclosures

- Marine and navy bulkheads and deckheads

- Isolate sound on doors for privacy

- Position as a curtain to separate and create an acoustic barrier

- Pipes and ducts

Features

- Conforms to MIL-PRF-24699B (SH) Type II - approved for use in military vehicles and navy ships

- Excellent soundproofing and fire-resistance properties

- Simple to cut and install through obstructions - providing flexibility around pipes, ducts, cables etc.

- Resistant to most chemicals, solvents and petrol

- Free from lead, odour-producing oils and bitumen

- Resistant to weather and UV light

- Tear resistant with high tensile strength - ability to be suspended in lengths of up to 16.4 ft (5 m)