Acoustic barrier solution for $21 billion Plaquemines LNG project

- Publication

- Petra Voet

- Product Types

- Industries

- Markets

- Liquefied Natural Gas

- Processing Plant

- Products

- Reading time 3 minutes

Quadzero™ MVT was successfully installed at one of the world’s most ambitious LNG projects - delivering proven acoustic performance and long-term protection from moisture and corrosion.

The Plaquemines LNG facility in Port Sulphur, Louisiana, with a nameplate capacity of 20 MTPA, developed by Venture Global, is one of the largest LNG export projects in the United States. The terminal includes the Gator Express pipeline system, consisting of two large-diameter pipeline segments connecting to the interstate network.

To support this infrastructure, Pyrotek was selected to provide critical acoustic and vapour insulation on the pipeline, including elbows, valves, and flanges. Pyrotek collaborated closely with the project’s engineering, procurement, and construction teams, as well as installation contractors, to deliver an engineered solution that met stringent performance, fire, and installation requirements.

Challenges

The LNG pipeline infrastructure and its hot, humid, seawater-adjacent location in Louisiana posed tough challenges. Cold pipelines exposed to warmer air created ideal conditions for internal moisture buildup, potentially leading to corrosion over time. The large-diameter piping systems required dual protection: strong acoustic control to meet regulatory and environmental noise limits, and a reliable vapour barrier to preserve insulation integrity over the pipeline’s lifetime, as repairs in LNG systems are costly and complex.

Installation needed to be efficient and dependable to keep pace with construction and the site’s massive scale. Material also had to offer better dimensional stability, water resistance, and low flammability.

Solutions

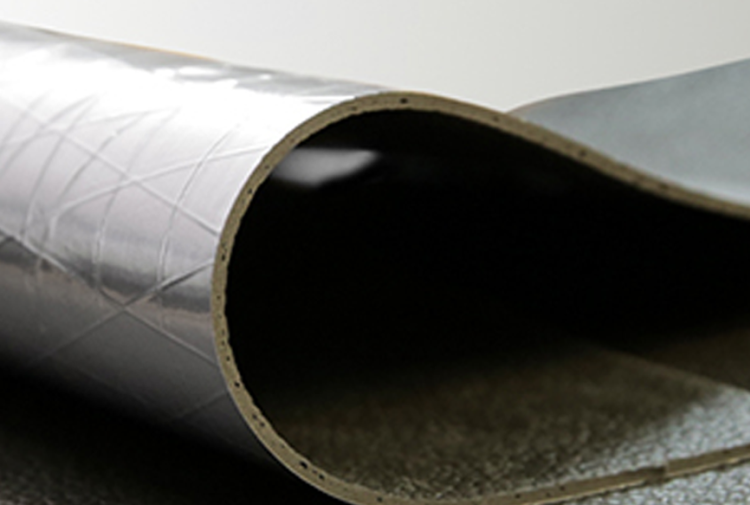

Pyrotek provided its specialized Quadzero™ MVT solution - a mass-loaded vinyl noise barrier integrated with a reinforced aluminium vapour membrane, specifically designed to act as a vapour barrier in critical applications where prevention of CUI (corrosion under insulation) is essential. It is purpose-built for hot and cold LNG pipe applications, reducing noise and controlling vapour transmission. The low permeability properties of MVT block moisture entry, maintaining thermal efficiency and preventing condensation within the insulation system, reducing the risk of corrosion.

The 5 kg/m² (1 lb/ft²) grade was specified for the pipeline segments as part of the complete insulation package, delivering effective sound attenuation and moisture protection in a single, efficient product layer. The advantage of Quadzero MVT is that it allows for thinner installation layers compared to traditional materials, resulting in lower material volumes and cost savings for the project. Additionally, it provides the acoustic performance required while supplying an added layer of moisture protection, further reducing the risk of CUI and enhancing the pipeline’s durability.

Quadzero MVT was applied along both segments of the Gator Express pipeline. In total, six containers of Quadzero MVT were delivered and installed along approximately 17.5 km (approximately 11 miles) of cryogenic pipeline systems. Feedback from the installation team was overwhelmingly positive, highlighting the product’s ease of handling and consistent high quality across the site.

To ensure a fully sealed system, Pyrotek’s Tape MVT was also supplied for sealing all joints and edges, creating a continuous, robust vapour barrier.

Results

The Plaquemines LNG project - now producing LNG while final construction phases continue - stands as a global benchmark in speed and scale. Its supporting infrastructure, including the Gator Express pipeline, ensures secure and flexible access to multiple low-cost natural gas resource basins, reinforcing the U.S.’s position as a leading LNG exporter. Pyrotek is proud to have contributed to this mission by delivering an insulation solution that combines performance, protection, and installation efficiency - proving its value in one of the world’s most critical energy projects.

A story of Persistance

The success at Plaquemines LNG is also the result of years of groundwork. Pyrotek first introduced the MVT concept to the LNG sector in 2018, presenting it to major engineering companies as a 2-in-1 solution combining both acoustic insulation and vapour barrier capabilities. Although there was immediate interest - and the material was well received by installers and engineers during early trials - changing long-established material specifications in LNG projects proved difficult.

Despite its technical advantages, MVT remained outside mainstream specifications for several years, as companies preferred traditional solutions they were more familiar with. Over time, Pyrotek refined its positioning, presenting MVT as an integrated noise barrier within full insulation systems rather than as a standalone replacement.

Plaquemines LNG facility image source: Venture Global