Expansion joints are high-quality products which are used in industrial equipment, plant units, machinery and pipelines. They have been proving their worth for many years in power engineering, HVAC, the waste incineration/disposal industry, the cement and steel industry and the chemicals industry, as well as in materials handling and the ceramic industry.

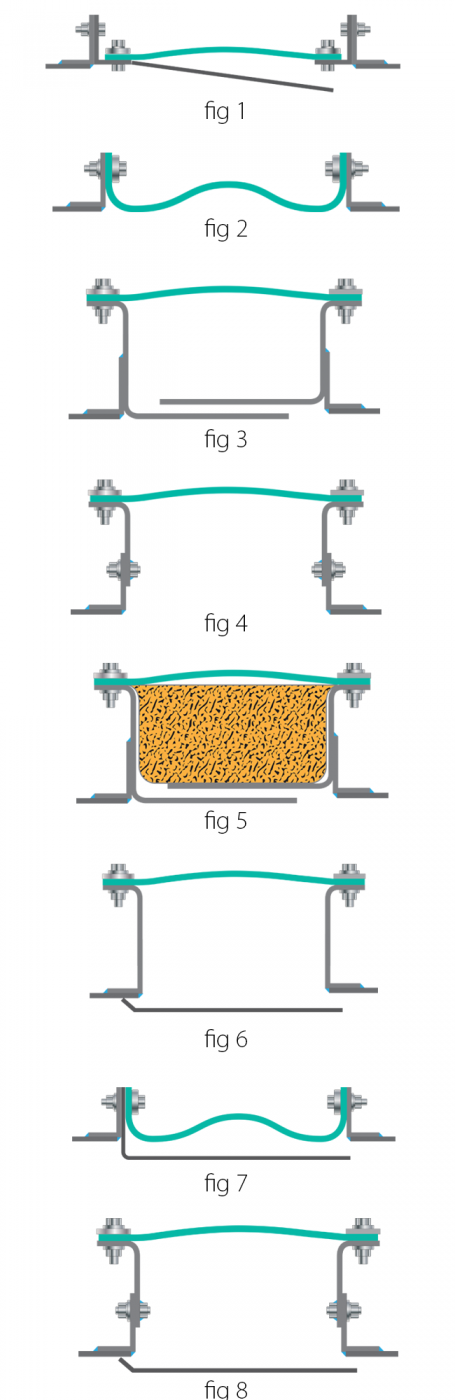

All exhaust gas duct work requires expansion joints or vibration eliminators to absorb any movement in duct work. Otherwise referred to as bellows, specialised solutions for chemical expansion and duct work also include thermal covers.

We manufacture a range of fabric and metallic expansion joints. The correct materials are selected depending on temperature and the type of corrosive gases present.

We supply fabric expansion joints made from high temperature fabrics and are also able to incorporate high density noise barrier materials to provide a sound barrier in joints on or near fans.

We offer a complete service including design, manufacture and supply of the fabric and metallic expansion and associated steel work.